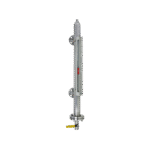

Magnetic Level Gauges

Magnetic Level Gauges &

Level Transmitter

Magnetic Level Gauges

Magnetic Level Gauges (MLGs) offer a clear and highly visible indication of liquid levels in tanks and vessels. Designed as a reliable alternative to traditional glass level gauges, MLGs are now widely used across industries due to their enhanced safety and durability. Unlike glass gauges, they eliminate the risk of chemical spillage from glass breakage and avoid direct contact between the process fluid and the indicator system.

Key Benefits:

High-clarity level indication

No direct contact between the indicator and process fluid

Eliminates glass breakage risks and chemical exposure

Types of Magnetic Level Gauges:

1. Flapper Type Magnetic Level Gauge

This type features an indicator system with bicolour magnetic rollers mounted on a rail within a protective housing. As the liquid level rises or falls, a magnetic float inside a non-magnetic chamber moves accordingly. The magnetic interaction between the float and the rollers causes the rollers to flip, displaying the liquid level with high visibility.

- Capsule Shuttle Type Magnetic Level Gauge

In this model, the indicator system includes a capsule shuttle enclosed within a glass tube. Similar to the flapper type, a magnetic float moves with the liquid level inside a non-magnetic chamber. The magnetic force between the float and the shuttle causes the capsule to travel in tandem with the float, providing an accurate visual indication of the level.

Technical Specification:

- Magnetic Level gauge applicable upto 100 kg/cm² and upto 300 °C

- Cryogenic application upto-196 ° C

- Jacketed design applicable

- For applicability in critical, acidic, cryogenic and high temperature zone

- IBR certified device available

- NACE, H2S service compatibility applicable

- Heat Tracing available

- Level 1 radiographed body available

- Helium Leak test Proved design @ 10 (-5) mbarlt/sec

- Viscous media (max upto 380 cst and upto 100 ° C) besides other, acidic, non-acidic, steam water media

- CE applicability

- Device fully compatible for conductive and non-conductive media

- Special float design to enable to meet low critical specific gravity

- Design applicability test with special media available

Applications

Industry :

- Refinery

- Petrochemical

- Chemical

- Power

- Radioactive

- Fertilizer

- Food

- Pharma

- Metal Industry Application

Download Datasheet

Magnetic Level Gauges

Magnetic Level Gauges

Certifications

Frequently Asked Questions

Get accurate, durable, and maintenance-free Magnetic Level Gauges , engineered for reliable fluid level monitoring across critical industrial applications. Designed to deliver clear visual indication without direct contact between the indicator and the process fluid, these gauges are ideal for environments where safety, precision, and long-term reliability are essential.